Clients expect stylish spaces with good acoustics—but if your wall panels fall short in performance or design, they may not return. That’s a costly risk for any B2B buyer.

To offer the best wooden slat wall solutions, prioritize panels with proven acoustic ratings, flexible design options, and reliable supply chains. Choosing the right manufacturer also ensures consistent quality and seamless delivery.

wooden slat acoustic wall

Your clients trust you to bring solutions that look good and perform well. But what defines a good solution? The answer lies in understanding their needs and matching those with the right acoustic performance, visual appeal, and supplier reliability. Let’s break it down.

What Acoustic Performance Metrics Should You Prioritize When Selecting Wooden Slat Panels?

Noise complaints, poor speech clarity, or echo-heavy environments—these are common issues in commercial interiors. If your acoustic panels can’t fix them, you lose credibility.

Prioritize panels with verified NRC ratings between 0.70 and 0.95, depending on the environment. These ratings show how much sound the panels can absorb, directly affecting comfort and usability of a space.

NRC rating acoustic panel

Why Acoustic Ratings Matter

When I talk with architects and interior designers, their first concern is usually performance. That’s why NRC (Noise Reduction Coefficient) is critical—it’s the most trusted metric in our industry. Here’s how it works:

| Environment | Recommended NRC | Common Issues Solved |

|---|---|---|

| Open offices | 0.75 – 0.90 | Echo, overlapping conversations |

| Conference rooms | 0.85 – 0.95 | Poor speech clarity |

| Hotel lobbies & lounges | 0.70 – 0.85 | General reverberation |

| Restaurants & cafés | 0.75 – 0.90 | Background noise interfering with talk |

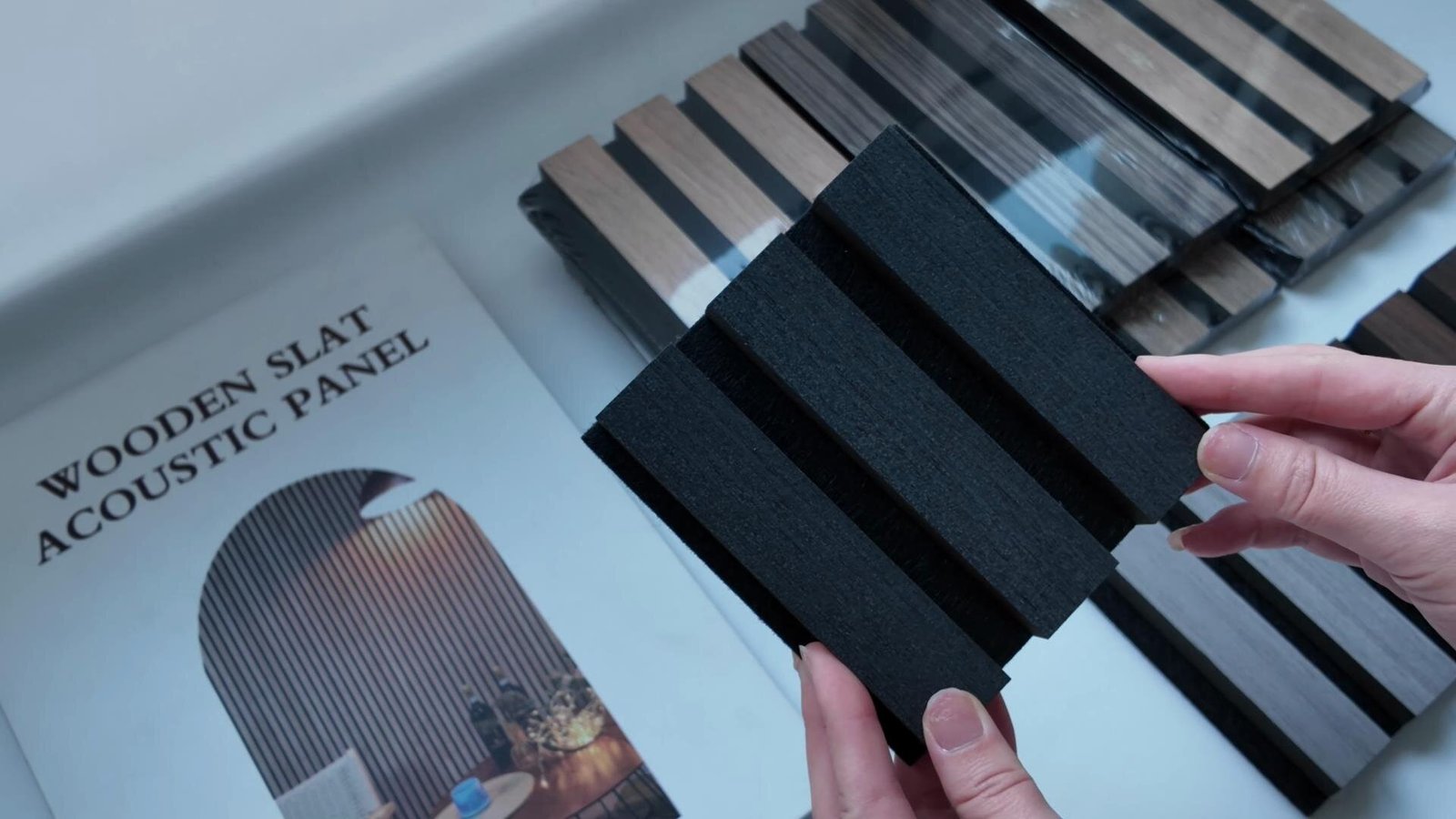

If you’re working with wooden slat acoustic panels, make sure they come backed with lab-tested acoustic data—not just design brochures. Look for panels with PET felt backing and 3D structure; these features boost absorption.

In one project, we supplied panels to a large coworking space in Toronto. The architect needed 0.85 NRC but also wanted a modern wood finish. We worked closely with them to test different panel configurations until we hit both targets.

How to Match Wooden Slat Wall Styles with Different Commercial Interior Design Requirements?

Your client loves the warm look of wood—but if it clashes with their branding or feels outdated, they won’t be impressed. That’s lost trust, and possibly, lost deals.

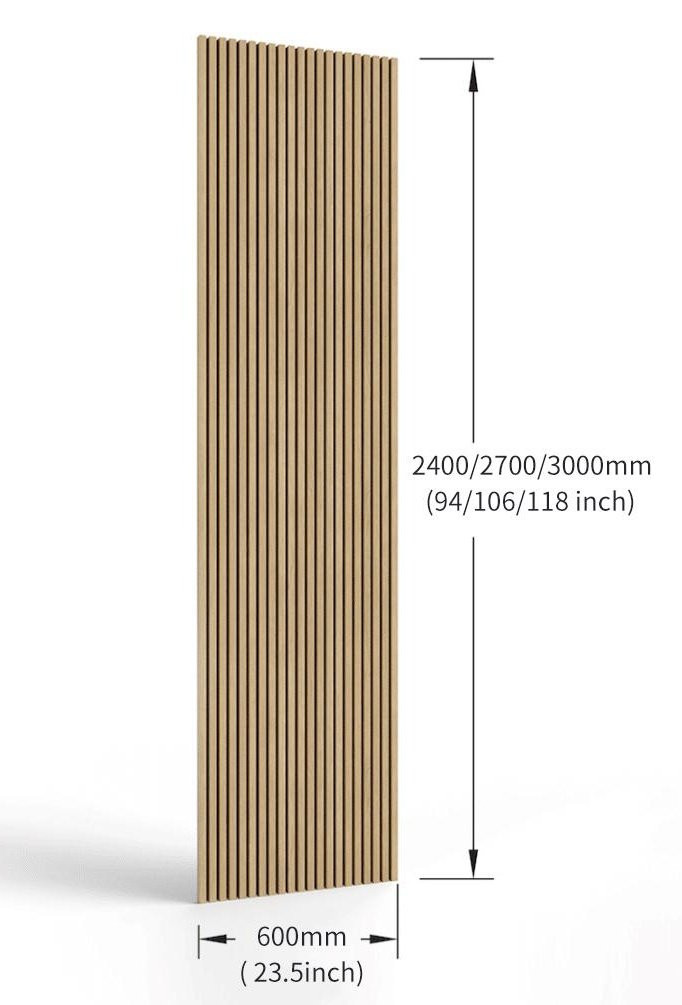

Choose wooden slat wall panels with flexible veneer options and modular configurations so you can tailor the design to suit offices, retail spaces, or hospitality settings.

modern wood wall panel design

Style Meets Functionality

Design isn’t just about looks—it’s a functional decision. Clients from different sectors want different things:

| Sector | Style Priority | Best Panel Choices |

|---|---|---|

| Tech offices | Sleek, minimal, matte finishes | Black oak or walnut lamella strips |

| Retail boutiques | Warm, textured, natural tones | Natural oak or smoked ash with subtle grain |

| Restaurants | Cozy and bold aesthetics | Custom slat widths with LED backlighting |

| Hotels & lounges | Luxury, symmetry, richness | Wide panel spacing with deep tone veneers |

Our slat panels are available in both natural wood veneers and technical wood films. Some designers want a Scandinavian vibe—light ash with narrow spacing. Others prefer bold contrast—dark walnut with wide gaps. A good panel system lets you do both.

And it’s not just color. Slat width, depth, and spacing all play roles in setting the mood. Our designers often create 3D renderings for clients using our panel library, helping them visualize the final look and sign off faster.

What Should B2B Buyers Look for in a Reliable Wooden Slat Panel Manufacturer?

Delays in production, quality issues, lack of support—these are common complaints in our industry. A good product alone isn’t enough.

Choose a manufacturer with in-house production, transparent quality control, international certifications, and proven experience with bulk orders and exports.

wooden panel supplier quality

More Than Just Panels

I’ve worked with procurement managers who’ve been burned by slow responses and missing certificates. So I tell them: vet the factory like you would vet a business partner.

Key criteria include:

| Evaluation Point | What to Look For |

|---|---|

| Production Capacity | ≥ 5 production lines, at least 30,000㎡ monthly output |

| Material Control | In-house cutting, veneering, backing, packing |

| Certifications | ISO9001, FSC, fire resistance, acoustic test reports |

| Logistic Experience | Sea freight packaging, container loading videos |

| Sample Policy | Fast delivery, real sample matching catalog quality |

| Response Time | Within 24h for inquiries, with clear documentation |

One Canadian distributor told me their last supplier vanished after sending samples. That’s why we keep full transparency—WhatsApp updates, pre-shipment photos, and real lead times. Our factory runs 5 lines and we ship to 7 countries monthly.

Conclusion

Delivering the best wooden slat wall solution means aligning performance, aesthetics, and supplier trust. When these three elements work together, your project—and your business—will stand out.