If you’re trying to choose between tambour panels, veneered MDF, or slat panels, you’re not alone. Each option has its own look, feel, and technical strengths—but which one truly fits your project?

Tambour panels differ from veneered MDF and slat panels in structure, material, and purpose. Tambour panels are flexible and decorative, veneered MDF offers affordability and a flat finish, while slat panels balance visual texture with sound absorption. The best choice depends on whether you need flexibility, acoustics, or a flat premium look.

Many designers and procurement professionals feel overwhelmed by the wide panel options available on the market. When you’re working with deadlines and budgets, a wrong choice could cost both time and reputation. This comparison is here to clear that fog, giving you direct, useful answers.

What Are the Key Material and Structural Differences Between Tambour Panels, Veneered MDF, and Slat Panels?

Every panel is not built the same—and assuming they are can create costly surprises. Understanding the makeup of each option helps avoid design mismatches and poor acoustic outcomes.

Tambour panels use narrow strips of wood veneer attached to a flexible backing. They curve easily and create a flowing, sculptural effect. Veneered MDF is a single flat board covered with a wood veneer. It looks good but doesn’t offer acoustic or design flexibility. Slat panels (like the ones we manufacture) are made from repeated MDF slats mounted on a PET felt backing. These offer acoustic absorption along with a bold visual rhythm.

panel structure comparison

Here’s a breakdown to make the differences easier to see:

| Feature | Tambour Panels | Veneered MDF | Slat Wall Panels |

|---|---|---|---|

| Structure | Flexible veneer strips on backing | Flat MDF board with veneer | MDF slats on acoustic felt |

| Flexibility | High – can bend around corners | None | Moderate – flat only |

| Acoustic Function | Very limited | None | High NRC with PET backing |

| Visual Appeal | Modern, fluid, elegant | Clean and flat | Bold, linear, textured |

| Applications | Columns, rounded walls, feature zones | Cabinets, office walls, flat surfaces | Offices, studios, commercial walls |

Tambour panels shine in custom, curved, or decorative installs. Veneered MDF fits clean corporate builds. Slat wall panels hit a sweet spot between form and function.

Which Panel Type Offers the Best Acoustic and Decorative Performance for Commercial Spaces?

Commercial interiors need more than looks—they need performance. If the space echoes or feels cold, aesthetics won’t save the day. Sound absorption and visual character must go hand-in-hand.

Slat wall panels offer the best acoustic and decorative balance. Their felt backing absorbs sound while the slatted surface adds rhythm and dimension. Tambour panels, while beautiful, offer little to no acoustic benefit. Veneered MDF performs worst in both areas—it’s just a flat surface with no absorption or structure.

To visualize their effectiveness:

| Panel Type | Acoustic Rating (NRC) | Decorative Value | Ideal Use Case |

|---|---|---|---|

| Tambour | 0.10 – 0.20 | High | Reception walls, curved designs |

| Veneered MDF | <0.05 | Moderate | Budget-friendly partitions, cabinets |

| Slat Panels | 0.60 – 0.85 | High | Meeting rooms, studios, hallways |

From experience, I’ve seen clients regret going with veneered MDF when they didn’t factor in sound quality. In one office project, we replaced all veneered boards after complaints about echo—slat panels fixed it instantly.

How Do Installation Methods and Lead Times Differ Across These Panel Types?

Time and ease of installation can make or break a commercial project. Each day lost to complex installation means extra costs and angry clients. So which panel type keeps things moving?

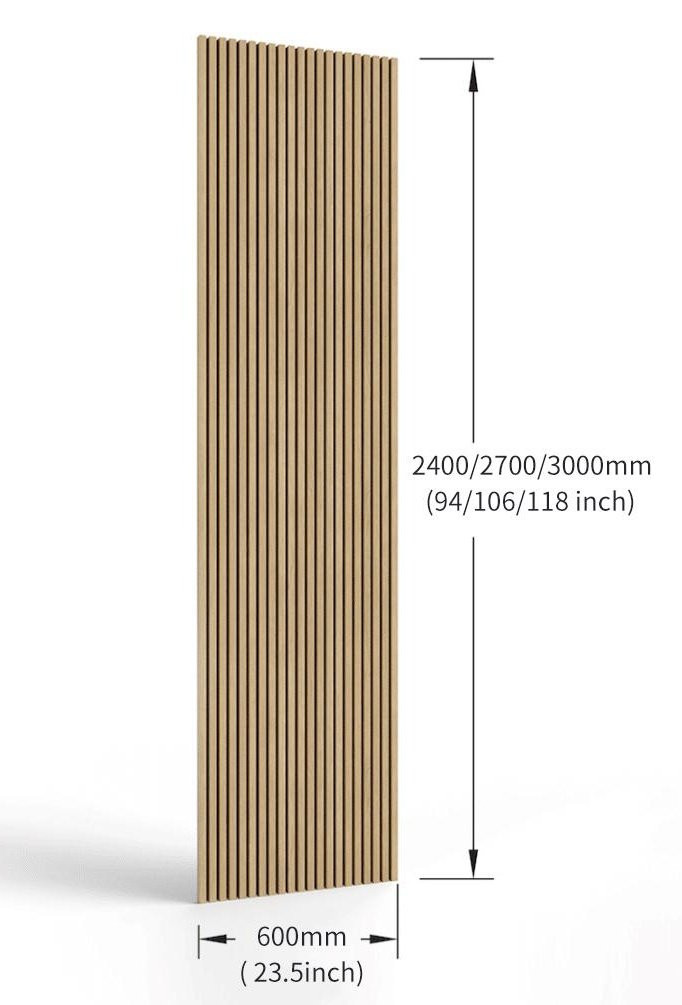

Tambour panels are lightweight and flexible, which makes them easy to install on curved surfaces with basic adhesives. Veneered MDF is heavier and needs precise framing and hardware, especially on vertical surfaces. Slat panels are typically supplied in modular sizes and come with an acoustic backing, making installation straightforward—most of our clients install them with nails or construction glue directly on battens or flat walls.

Let’s compare how they differ on-site:

| Panel Type | Install Complexity | Tools Needed | Lead Time (Average) | On-Site Labor Time |

|---|---|---|---|---|

| Tambour | Easy | Utility knife, adhesive | 10–15 days | Low |

| Veneered MDF | Moderate | Saw, brackets, screws | 12–20 days | Medium |

| Slat Panels | Easy | Nail gun, glue, saw | 10–18 days | Low |

From our factory, we always try to maintain a 15-day turnaround, but clients who order veneered MDF often have to wait for special sizes. Tambour and slat panels, being more standardized, get shipped faster.

Conclusion

Choosing the right panel means balancing design, acoustics, and installation. For most commercial spaces, slat panels offer the best mix of beauty and performance, while tambour suits curved designs and MDF fits tight budgets.