Buyers often pick the wrong panels. Poor quality wastes money and ruins projects. What should you check to get it right?

The key factors are material quality, sound absorption, thickness, certifications, and supplier reliability. Choose real wood, high NRC ratings, the right thickness, valid safety certs, and a dependable supplier. This keeps your panels effective and long-lasting.

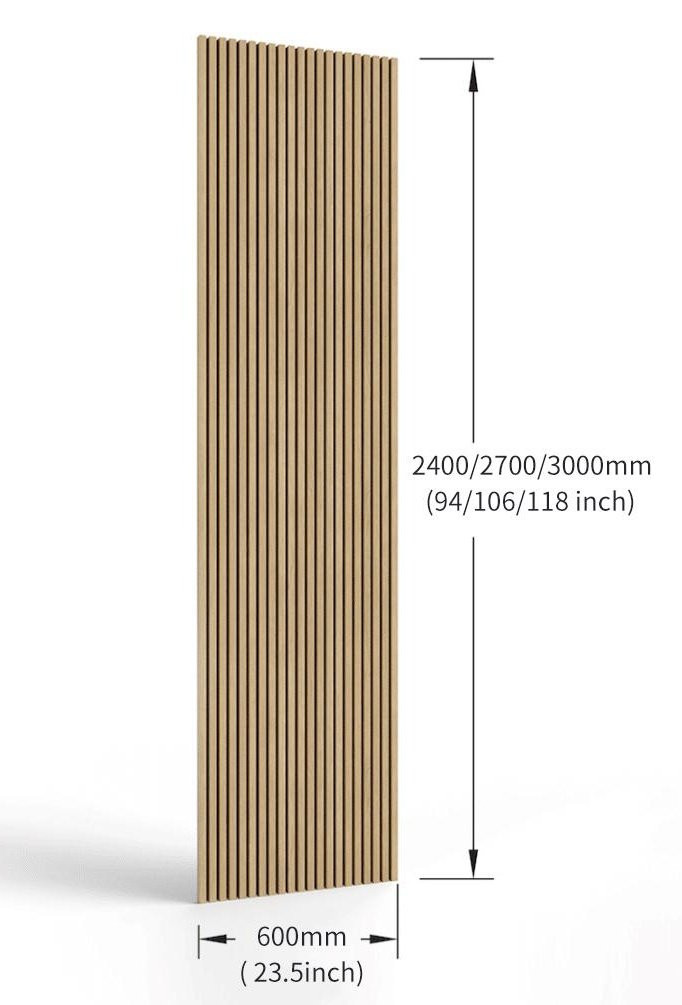

wood acoustic panels

I’ve run NF Decor in China for years. I’ve seen what works and what doesn’t. Keep reading—I’ll guide you through the details.

What to Look for When Buying Acoustic Panels?

Cheap panels can fail fast. I’ve had clients like Victor from the USA learn this the hard way. What should you focus on first?

Look for material quality, sound performance, and certifications. Go for real wood or MDF, NRC ratings above 0.8, and certs like CE or FSC. These protect your investment.

checking acoustic panels

Victor once got panels that warped. Now, he double-checks everything. Let me explain why these factors matter.

Material Makes a Difference

At NF Decor, I use real wood veneers on our slat panels. They last longer than particleboard or cheap MDF. Victor had panels peel once—never again. Good materials save you trouble.

Sound Performance Counts

The NRC rating shows how well panels absorb sound. I target 0.8 or higher. Victor’s old panels had no rating and didn’t sell. Always ask for test reports to be sure.

Certifications Keep You Safe

Safety and eco-standards are a must. I’ve seen shipments stopped over missing certs. Victor now insists on CE and FSC. It’s a simple check that avoids big problems.

Here’s a quick table:

| Factor | Why It Matters |

|---|---|

| Material | Impacts durability |

| NRC Rating | Shows sound absorption |

| Certifications | Proves safety and quality |

Check these, and you’ll dodge Victor’s headaches.

What Is the Best Wood for Acoustic Paneling?

Wood choice can ruin your panels. I’ve seen clients struggle with oak, walnut, or MDF. Which one stands out?

Oak and walnut are the best for durability and looks. They’re strong and resist moisture. MDF works for tight budgets but needs care.

wood types for panels

I sent oak panels to Malaysia once—no issues in humidity. MDF didn’t hold up. Here’s why wood matters.

Oak and Walnut Win

Oak is my favorite. It’s dense and great for sound. Walnut looks rich and suits fancy spaces. Both handle finishes well, matching any style you need.

MDF Has Limits

MDF costs less and shapes easily. I use it for some designs. But moisture can wreck it. For Victor’s showroom, I’d pick oak over MDF any day.

Here’s a comparison:

| Wood Type | Pros | Cons |

|---|---|---|

| Oak | Tough, moisture-resistant | Costs more |

| Walnut | Great look, strong | Pricey |

| MDF | Cheap, flexible | Weak in wet conditions |

Pick what fits your space and wallet. Victor sticks to oak now—it sells fast.

What Makes Good Acoustic Panels?

Looks alone don’t cut it. I’ve seen clients chase style and miss performance. What really makes panels great?

Good panels mix sound absorption, durability, and design. They need high NRC ratings, strong materials, and a style that fits. Miss one, and they fail.

quality acoustic panels

Victor bought pretty panels that didn’t work. Customers hated them. Let’s look at what counts.

Sound Comes First

No NRC rating means no noise control. I test every panel at NF Decor. Victor won’t buy without proof now—it’s a game-changer.

Durability Lasts

Panels should stay solid for years. Real wood or dense felt does the trick. Victor’s cheap ones broke fast. Quality materials pay off.

Design Sells

Style boosts value. Our slats and hexagons are hits in the USA. Victor says they move quick. Looks matter as much as function.

Here’s a breakdown:

| Feature | Why It’s Key |

|---|---|

| NRC Rating | Cuts noise effectively |

| Material Quality | Ensures long life |

| Design | Adds appeal and sales |

Get these right, and your panels shine.

How to Pick Acoustic Panels?

Choosing panels can overwhelm you. Quotes and specs pile up. How do you decide wisely?

Pick panels by testing samples and trusting your supplier.Check weight, verify certs, and confirm shipping. A solid supplier seals the deal.

selecting acoustic panels

Victor got stuck with delays and fakes once. Now, he uses my method. Here’s how it works.

Samples Tell the Truth

I send samples to clients. Victor tests them—weight, finish, feel. Good panels stand out when you hold them.

Check Every Detail

Get certs and terms in writing. I’ve seen suppliers dodge questions. Victor demands clarity now—it keeps him safe.

Shipping Must Work

Delays hurt sales. I track every order at NF Decor. Victor relies on that to hit his deadlines.

Here’s a guide:

| Step | Why It Helps |

|---|---|

| Test Samples | Shows real quality |

| Verify Details | Stops scams |

| Check Shipping | Keeps things on time |

Do this, and you’ll choose winners.

What Is the Best Thickness for Acoustic Panels?

Thickness trips people up. I’ve had clients wonder if more is always better. What’s the right size?

The best thickness is 2 to 4 inches for most needs. Thicker handles low sounds, but 2 inches fits general use. Match it to your space.

acoustic panel thickness

I told a studio owner in Australia to use 3 inches—perfect results. Let’s see why it matters.

Thickness Affects Sound

Low frequencies need more depth to absorb. Offices do fine with 2 inches. Studios might need 3 or 4 for bass.

Balance Cost and Space

Thicker costs more and takes room. I help Victor pick what works. His showroom uses 2.5 inches—just right.

Here’s a table:

| Thickness | Best Use |

|---|---|

| 2 inches | Homes, offices |

| 3 inches | Studios, theaters |

| 4 inches | Heavy bass zones |

Match thickness to your goal. Victor adjusts per job.

What Are the Characteristics of Acoustic Panels?

Panels seem basic, but they’re not. Victor asked me what makes them special. What defines them?

Acoustic panels absorb sound, cut echoes, and boost clarity. They use wood, felt, or foam, with different thicknesses and designs for any space.

Victor needed options for offices and studios. Let me show you their key traits.

They Absorb Noise

Panels trap sound waves. The NRC rating proves it. I keep ours at 0.8 or better—Victor loves the results.

Materials Vary

Wood looks great. Felt is eco-friendly. Foam saves money. I mix them at NF Decor. Victor picks wood for profit.

Designs Adapt

Slats or hexagons change looks and sound. Hexagons scatter noise well. Victor uses both for variety.

Here’s what they do:

| Trait | Effect |

|---|---|

| Absorption | Lowers noise |

| Material | Sets cost and strength |

| Design | Shapes style and function |

Know these, and you’ll pick smart.

Conclusion

Check materials, thickness, certs, and suppliers when buying panels. I’ve built NF Decor on quality. Email me at nuofei@nfdecor.com for reliable options.