Picking the wrong panels stings. I’ve seen projects flop—echoes everywhere, ugly walls, money down the drain. How do I help you dodge that disaster?

Choose wood acoustic panels based on material, thickness, and design. Go for real wood, NRC ratings above 0.8, and looks that match your space. This keeps your project on track.

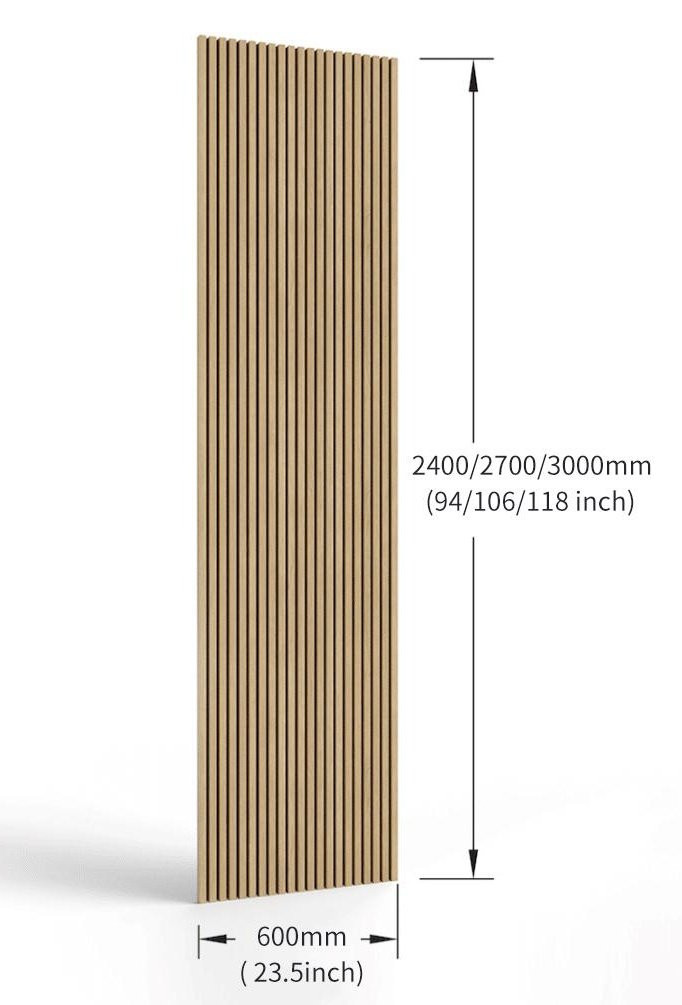

wood acoustic panels

I’ve shipped panels worldwide—Canada, the UK, you name it. Clients like George rely on me to simplify this. Let’s figure it out together.

How to Choose Acoustic Panels?

Choosing panels can feel risky. George once got stuck with junk panels that fell apart—his clients were mad. How do you pick the right ones every time?

Focus on quality, performance, and supplier reliability. Check the materials, sound ratings, and certifications. A solid supplier saves you from trouble.

choosing acoustic panels

What to Look For

Materials are the starting point. I use real wood like pine or oak for my slat panels—never flimsy MDF. George’s old supplier sent him particleboard. It warped in Canada’s humidity. Lesson learned. Sound performance comes next. I target an NRC of 0.8 or higher. Lower than that won’t work for studios or offices. George’s showroom needed quiet—my panels fixed it. Supplier reliability is the final piece. I’ve had clients in Australia and Germany rave about my on-time deliveries. George hates delays—they hurt his sales. I get that.

Here’s a quick checklist:

| Factor | Why It Matters |

|---|---|

| Material | Impacts durability and style |

| NRC Rating | Shows how well it controls sound |

| Supplier Reliability | Guarantees you get it on time |

George now asks for samples. It’s a smart move. You should too—hold the panel, check the finish. It’s the best way to avoid regrets.

What Are the Best Acoustic Panels for Soundproofing?

Soundproofing trips people up. I’ve had clients think any panel works—wrong. What actually gets the job done?

The best panels for soundproofing are thick, dense, and installed right. Wooden slat panels with felt backing absorb and block noise. Quality matters more than piling on panels.

soundproofing panels

Sorting Out the Details

Soundproofing and absorption aren’t the same. Soundproofing stops outside noise. Absorption cuts echoes inside. My panels handle both, but setup is everything. Thicker panels work better for soundproofing. My 3D felt panels are dense and deep—they quiet things down fast. I sent some to a studio in France, and they went from chaotic to silent. Installation can make or break it. Gaps let sound sneak through. I tell clients to use pros or follow good guides. George tried DIY once—it was a mess. He sticks to experts now.

Here’s a comparison:

| Type | Best For |

|---|---|

| Wooden Slats | Style and decent soundproofing |

| 3D Felt | Top absorption and blocking |

| Hexagons | Cool look, solid absorption |

George uses wooden slats in his showroom. They’re stylish and cut noise. For tougher jobs, I push felt panels. They’re a step up.

What Are Professional Acoustic Panels Made Of?

Cheap panels fool people. I’ve seen suppliers skimp—big mistake. What’s inside the pro stuff?

Professional panels use high-density stuff like real wood, felt, or fiberglass. They’re built tough and work well. Foam’s a no-go—it’s too weak.

Breaking Down the Materials

Wood is king. I use pine or oak for my slats—strong and good-looking. Cheap panels go with MDF or plastic—they don’t last. George won’t buy those anymore. Felt’s a champ too. Mine’s recycled polyester—green and effective. It grabs sound across the board. Foam doesn’t even come close. Fiberglass shows up in some panels, but I skip it. It’s messy, and clients like George want clean setups. Wood and felt are safer bets.

Here’s the rundown:

| Material | Pros |

|---|---|

| Real Wood | Tough and sharp-looking |

| Recycled Felt | Green and high-performing |

| Fiberglass | Good absorption, but messy |

George loves wood’s vibe. His clients agree. I stick with it because quality’s in my blood—grew up around woodworking.

What Is the Best Thickness for Acoustic Panels?

Thickness puzzles folks. I’ve had clients wonder if thin panels cut it—usually not. What’s the right size?

The best thickness is 2 to 4 inches. Thicker ones tackle low sounds better. For most rooms, 2 inches does the trick.

panel thickness

How Thickness Works

Thicker panels grab more bass. My 3D felt panels are 3 inches—they’re great for music rooms. A German studio loved them for that. For offices, 2 inches is fine. My slats with felt hit that mark—they cut chatter without taking up space. George’s showroom uses them, and they fit perfectly. Thin panels, like 1 inch, only handle high pitches. They won’t help with deep noise.

Here’s a guide:

| Thickness | Best For |

|---|---|

| 1 inch | High pitches only |

| 2 inches | Offices, general use |

| 3-4 inches | Studios, bass-heavy spots |

George sticks to 2-inch slats. They’re sleek and effective. For home theaters, I’d go thicker. It depends on your space.

What Is the Difference Between Soundproof Panel and Acoustic Panel?

Labels mix people up. I’ve had clients order the wrong type—annoying. What sets them apart?

Soundproof panels block noise; acoustic panels absorb it. Both help with sound, but they tackle different problems. Pick what fits your need.

Clearing the Confusion

Soundproof panels are heavy. They stop noise from crossing walls—think concrete or vinyl. Acoustic panels are lighter. They soak up echoes inside. My felt and wood panels do this well. Sometimes you need both. A studio might block street noise with soundproofing and use acoustic panels for clarity inside. George only needed acoustic panels—his showroom had echo issues, not outside noise.

Here’s the difference:

| Type | Function |

|---|---|

| Soundproof | Stops outside noise |

| Acoustic | Cuts inside echoes |

A company in Malaysia asked me this once. I told them to nail down their goal first. It saves time.

How Many Acoustic Panels Do I Need to Soundproof a Room?

Counting panels throws people off. I’ve seen clients buy too many or too few—both stink. How many do you need?

For basic coverage, use one panel per 10-15 square feet. Room size, shape, and use change the number. Measure carefully.

Figuring It Out

Start with wall space. A 200 sq ft room might need 15-20 panels. That’s a rough start. Shape matters too—corners and ceilings can need more. I sketch it out first. Purpose changes things. Studios need more than offices. George’s showroom took 25 panels to get it right. I helped an Australian distributor with this. He mapped his space and nailed the count.

Here’s a basic formula:

| Room Size (sq ft) | Panels Needed |

|---|---|

| 100-150 | 10-15 |

| 150-250 | 15-25 |

| 250+ | 25+ |

George used this and got it perfect. Plan ahead—it works.

What Insulation Is Best for Acoustic Panels?

Insulation trips buyers up. I’ve had clients ask if it’s needed—sometimes it is. What’s the top choice?

The best insulation is high-density felt or fiberglass. They boost absorption without bulk. Not every panel needs it, though.

Picking the Right One

Felt’s my favorite. It’s eco-friendly and works great. My slat panels have felt backing—it pulls double duty. Fiberglass is solid but messy. I only use it if I have to. Foam’s cheap, but it’s weak—skip it. A UK client wanted extra quiet. I sent felt-backed panels, and they loved it. For outdoor stuff, I use weatherproof options.

Here’s how they stack up:

| Insulation | Pros |

|---|---|

| Felt | Green, easy to use |

| Fiberglass | Strong absorption, but dusty |

| Foam | Cheap, but not great |

George picks felt—it’s clean and effective. I agree—it’s the smart move.

Conclusion

Choosing wood acoustic panels needs focus—quality materials, right thickness, and reliable suppliers like NF Decor. Email me at lillian@nfdecor.com for help.