I’ve lost sleep over bad deals. Suppliers promise the world, but deliver junk—or charge too much. How do I pick acoustic panels that balance cost and quality?

To compare prices and quality, check material, certifications, and supplier reliability. Focus on wood type, sound absorption ratings, and customer reviews. This cuts through the noise and saves money.

comparing acoustic panels

I’ve been burned before—cheap panels that crumbled in months. Now, I run NF Decor with five production lines, and I’m sharing what I’ve learned. Let’s dive in.

What to Look for When Buying Acoustic Panels?

Quality keeps me up at night. Mark, a client in Canada, once got stuck with flimsy panels from a shady supplier. What should he—and you—watch for?

Look for durability, sound performance, and certifications. Real wood or felt, NRC ratings above 0.8, and legit safety certificates matter. Skip the fakes—they waste time and cash.

acoustic panel quality check

I’ve dealt with picky distributors like Mark for years. He’s assertive, knows sales, but misses technical details. Here’s how I break it down for him—and you.

Key Factors to Check

Running a factory in China, I’ve seen suppliers cut corners. It’s personal for me—my reputation’s on the line. Start with materials. Wooden slat panels should use solid wood, not particleboard. Felt panels need recycled fibers for strength. Cheap stuff falls apart fast.

Next, sound performance. The Noise Reduction Coefficient (NRC) tells you how much sound a panel absorbs. I aim for 0.8 or higher at NF Decor. Mark once bought panels with no rating—useless for his showroom. Test reports prove it works.

Certifications matter too. Fire safety and eco-standards like CE or FSC show a supplier’s serious. I’ve had clients in the USA and UK reject shipments over missing paperwork. It’s a hassle, but it protects you.

Here’s a quick guide:

| Factor | Why It Matters |

|---|---|

| Material | Affects lifespan and look |

| NRC Rating | Measures sound control |

| Certifications | Ensures safety and quality |

Mark learned this the hard way. Now, he trusts my panels. You can too—focus on these, and you’ll spot the good deals.

Are All Acoustic Panels the Same?

I used to think panels were all alike. Then a shipment of warped hexagons cost me a client. Are suppliers really offering the same thing?

No, acoustic panels vary widely. Differences in design, thickness, and build quality affect performance. A good panel absorbs sound and lasts—cheap ones just sit there.

I’ve shipped to Canada, Australia, and beyond. Each market has fakes lurking. Let’s unpack what sets panels apart.

Spotting the Differences

Not all panels are equal—I learned that fast. Take design. My hexagon panels scatter sound better than flat ones. Thickness counts too—thicker panels, like my 3D felt, handle low frequencies. Thin ones don’t.

Build quality is huge. I’ve seen suppliers glue panels so poorly they peel in humid climates like Malaysia. My factory uses strong adhesives and real wood slats. It’s why clients stick with me.

Here’s how they differ:

| Feature | Impact |

|---|---|

| Design | Changes sound patterns |

| Thickness | Boosts bass absorption |

| Build Quality | Determines durability |

Mark once asked why my panels cost more. I showed him a competitor’s sample—it cracked in my hands. He got it. Test samples yourself—weight and sturdiness tell the story.

Which Acoustic Panels Are Best?

Best is a big word. I’ve had construction firms in Germany demand top-tier panels—others just want cheap. Which ones really win?

The best acoustic panels match your needs. Wooden slats for style, hexagons for modern flair, felt for eco-friendly power. Quality beats price every time.

best acoustic panels

I’ve spent years perfecting my line at NF Decor. Customers like Mark need specifics, so let’s narrow it down.

Finding Your Fit

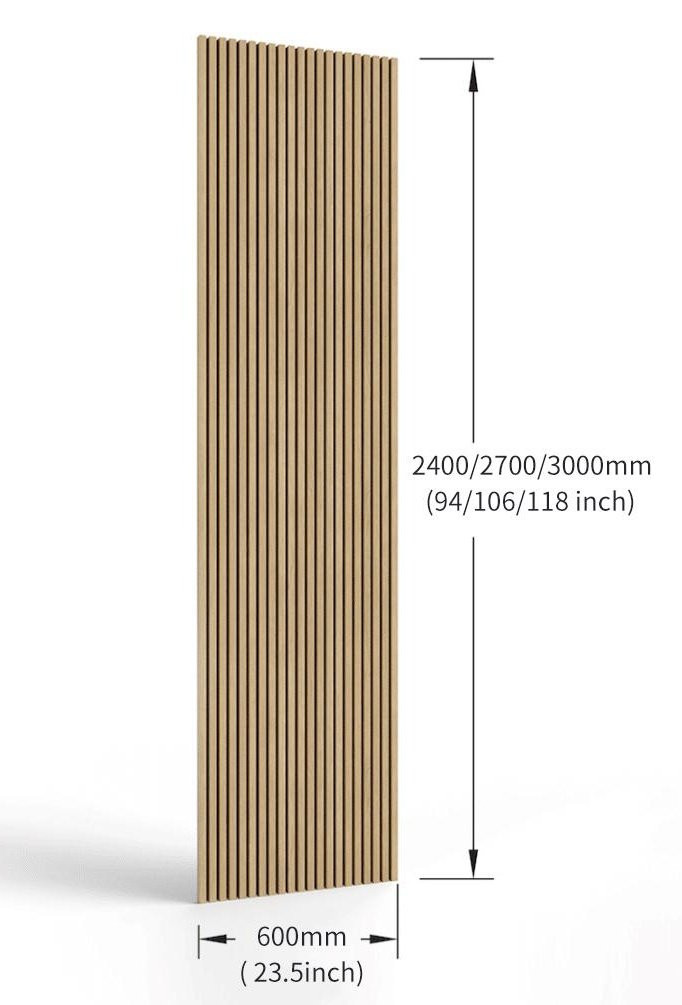

Best depends on you. I export to the USA, UK, and more—each client’s different. Wooden slat panels suit showrooms—they look sharp and cut noise. Mark swears by them for resale.

Hexagons shine in trendy spaces. A UK client used them in a studio—sound was crystal clear. Felt panels? Big in Australia for green builds. They’re light, sustainable, and strong.

Here’s a breakdown:

| Type | Best For |

|---|---|

| Wooden Slats | Style and sound |

| Hexagons | Modern spaces, scattering |

| Felt | Eco-friendly, versatile |

I tweak production based on feedback. Mark likes competitive pricing, but won’t skimp on quality. Pick what fits your space—don’t just chase the lowest bid.

How to Pick Acoustic Panels?

Choosing feels overwhelming. Quotes pile up, specs blur—I’ve been there. How do I make the right call without regret?

Pick panels by testing samples and checking logistics. Feel the weight, ask for certs, and confirm shipping timelines. A reliable supplier seals the deal.

picking acoustic panels

Mark’s pain points—delays, bad communication—hit home. I’ve built my business to avoid that. Here’s my process.

Step-by-Step Selection

I tell clients like Mark to start with samples. Hold them—good panels feel solid. I sent him a wooden slat piece; he liked the heft. Cheap ones are flimsy.

Ask questions. Certifications, lead times, payment terms—get it in writing. I’ve had suppliers dodge me, and it’s a red flag. Logistics matter too. Delays kill sales, especially in peak seasons.

Here’s my checklist:

| Step | Why It Helps |

|---|---|

| Test Samples | Confirms quality |

| Verify Certs | Avoids fraud |

| Check Shipping | Prevents delays |

Mark now calls me first. He knows I deliver—literally. At trade shows, I push this: touch the product, trust the supplier. It works.

Conclusion

Comparing acoustic panels takes work—check materials, test samples, and pick a supplier like NF Decor who delivers quality and trust. Reach me at nuofei@nfdecor.com for the real deal.