Tambour wall panels are making waves in commercial design—but many B2B buyers still don’t understand what makes them so special.

Tambour wall panels are decorative architectural elements made from thin, evenly spaced slats attached to a flexible backing. Architects favor them for their modern appearance, acoustic benefits, and ease of installation.

tambour wall panels in modern office

Even if you’re familiar with wood wall panels, tambour panels offer something different. Their grooved texture and curve-friendly design bring softness and rhythm to harsh interiors. In this article, I’ll walk you through what tambour wall panels are, how they’re made, why architects choose them—and what you, as a B2B buyer, must know before sourcing them from manufacturers like us.

How Are Tambour Wall Panels Made and What Materials Are Commonly Used?

If you’ve ever seen a wall with smooth wooden grooves that look like waves in motion, you’ve likely seen tambour panels in action.

Tambour panels are made by laminating thin wood slats onto a flexible or rigid base, often using MDF, plywood, or acoustic felt. The surface veneer can range from real oak to technical wood, allowing for different finishes and textures.

tambour panel construction materials

The process starts by selecting the base—usually MDF or flexible plywood—depending on whether the panel needs to bend around curves. Then, slats are either carved or attached onto the surface. These slats can be made from solid wood for a premium effect or from veneer to reduce cost and weight.

Materials Used in Tambour Panels

| Component | Material Options | Notes |

|---|---|---|

| Core/Back Panel | MDF, flexible plywood, acoustic felt | Rigid for flat walls, flexible for curves |

| Slats | Solid wood, technical veneer | Veneer is lighter and more cost-effective |

| Surface Finish | Oak, walnut, black ash, teak | Matches design schemes in hotels, offices |

| Adhesive | Industrial hot melt glue | Ensures long-lasting adhesion |

At NF Decor, we prefer veneered MDF slats on black PET felt for commercial clients. It balances aesthetics, cost, and functionality. For high-end projects, we sometimes use real wood veneer to create a richer tactile experience.

What Functional and Aesthetic Benefits Do Tambour Panels Offer in Commercial Spaces?

Plain drywall won’t leave an impression. But textured wall panels do. That’s why tambour panels are a favorite in modern commercial spaces.

Tambour panels offer excellent sound diffusion, hide wall imperfections, and bring a soft, modern rhythm to interiors—making them ideal for hotels, lobbies, and open-plan offices.

tambour panels in commercial design

I’ve seen tambour panels used in airport lounges, hotel corridors, and corporate receptions. They not only soften acoustics but also add depth and texture that painted walls can’t. That’s especially important when a brand wants to project warmth and elegance.

Benefits of Tambour Wall Panels

1. Acoustic Performance

Tambour slats break up sound waves. When mounted on felt, they further absorb noise. That’s why open offices and conference rooms love them.

2. Visual Impact

The repeating grooves give movement to otherwise flat walls. Whether horizontal or vertical, they add rhythm to the space.

3. Easy Installation

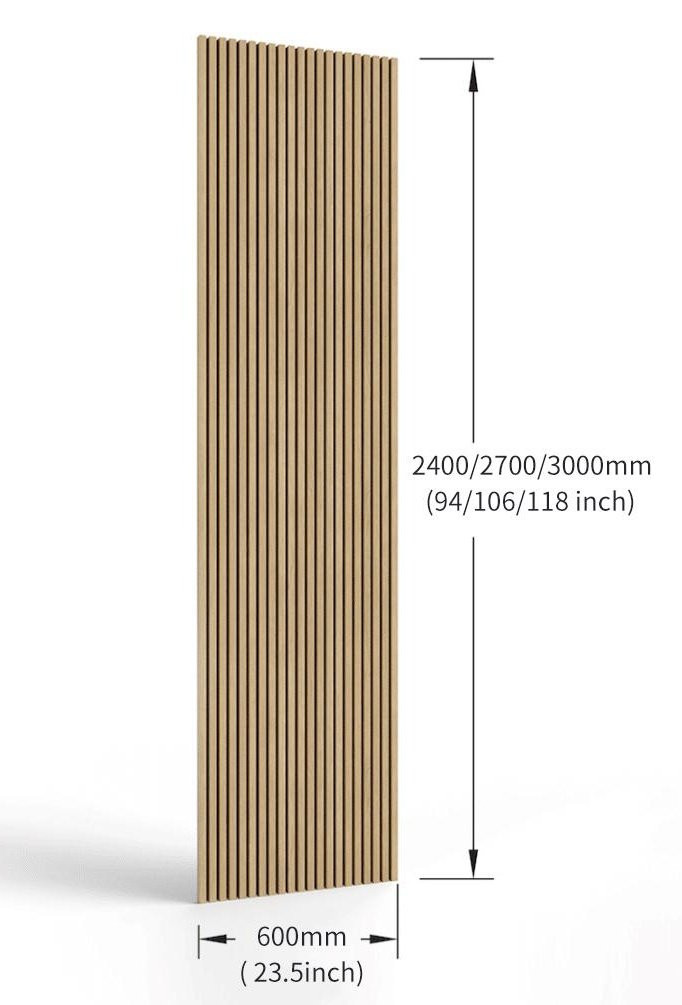

These panels come in prefabricated sizes, easy to mount with screws or adhesive. No need for on-site customization.

4. Versatile Application

Use them behind reception desks, along corridors, in elevator lobbies, or as full accent walls. They instantly raise the perceived value of a space.

5. Design Flexibility

From natural oak to bold black ash, tambour panels work across design themes—Scandinavian, industrial, contemporary, and more.

Here’s a tip: many designers choose darker tones for dramatic effect and lighter ones to open up a space. Offering both in your product catalog can help attract more clients.

What Should B2B Buyers Consider When Sourcing Tambour Wall Panels from Manufacturers?

You’ve seen the appeal. But as a B2B buyer, design alone isn’t enough. You need panels that are consistent, certified, and easy to ship.

When sourcing tambour wall panels, check for consistent slat spacing, surface finish quality, acoustic backing options, available certifications, lead time, and shipping strength.

In my own sourcing experience, I’ve had clients return to me with horror stories: uneven slat widths, warped panels after installation, or shipping damage due to poor packaging. These are avoidable—if you work with the right supplier.

Key Considerations for Buyers

| Factor | Why It Matters | What to Ask Your Supplier |

|---|---|---|

| Surface Consistency | Impacts visual appeal and project finish | Can I see a video of recent production output? |

| Material Options | Affects price, weight, and sustainability | Do you offer both solid wood and veneer slats? |

| Certification | Required for hotel or office projects in many regions | Do you have FSC, ISO, or fire-retardant tests? |

| Acoustic Performance | Needed for open-plan spaces | What’s the NRC rating if felt backing is used? |

| Packaging Quality | Avoids damage during transport | How do you pack panels for export? |

| Lead Time | Ensures timely installation | What’s your standard production and shipping time? |

I always recommend asking for physical samples before bulk purchase. It’s the only way to feel the texture and judge real-world quality. At NF Decor, we provide free samples for qualified projects and can customize sizes if needed.

Conclusion

Tambour wall panels aren’t just decorative—they solve real acoustic and aesthetic challenges in commercial interiors. Know what to look for, and they’ll become one of your most effective design tools.